Understanding The Versatility Of Galvanized Square Steel: A Comprehensive Guide

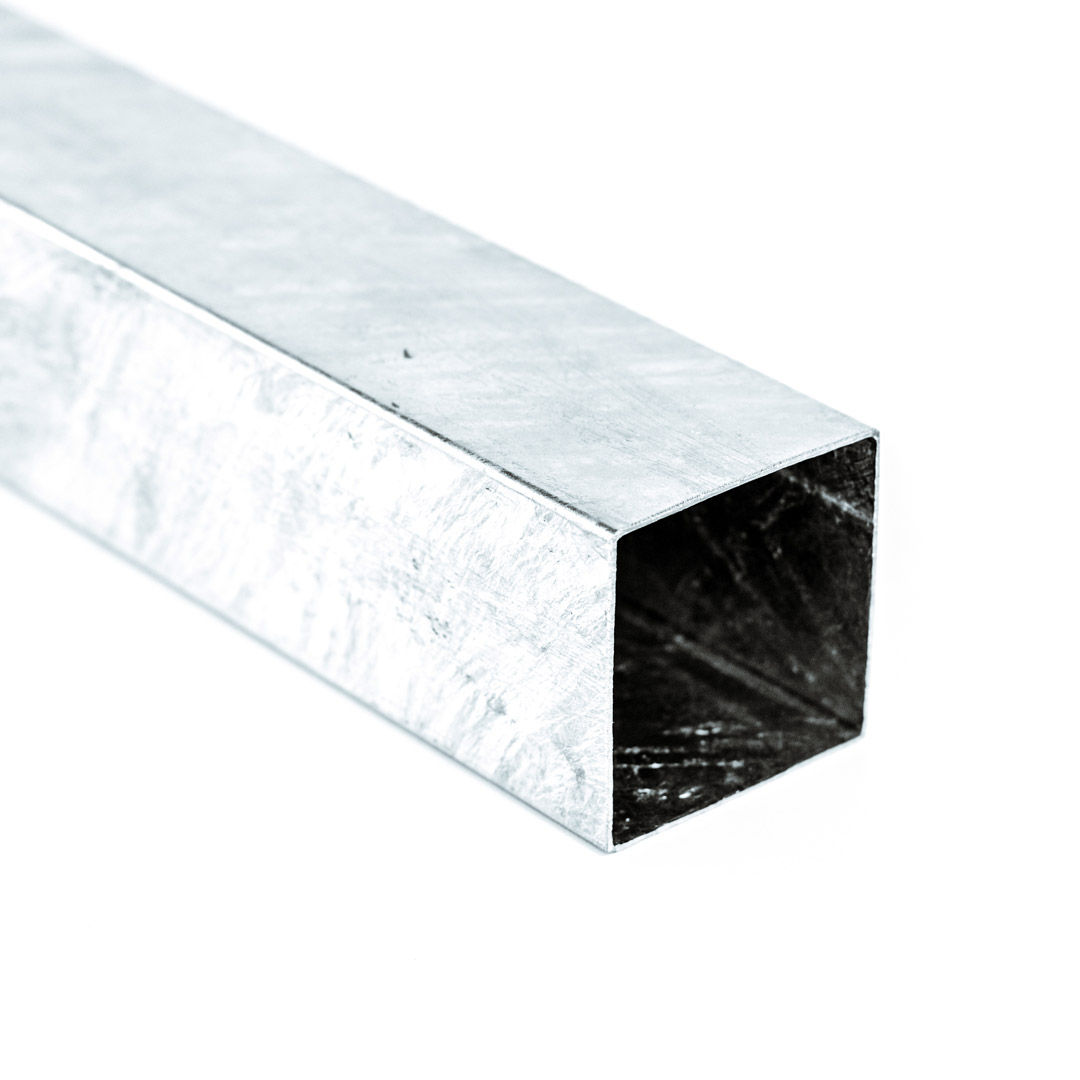

Galvanized square steel stands as a cornerstone material in modern construction and manufacturing industries due to its durability and corrosion resistance. This remarkable material undergoes a specialized zinc-coating process, which fortifies its strength and ensures longevity in diverse environmental conditions. Whether utilized in building structures, automotive components, or household fixtures, galvanized square steel remains a preferred choice for professionals and DIY enthusiasts alike. Its widespread adoption stems from its ability to withstand harsh elements while maintaining structural integrity, making it indispensable across various sectors.

The demand for galvanized square steel has surged significantly over the years, driven by advancements in technology and evolving construction practices. As industries prioritize sustainability and cost-effectiveness, this material offers a practical solution that balances functionality with environmental considerations. Its resistance to rust and ability to endure extreme weather conditions make it an ideal choice for both indoor and outdoor applications. Furthermore, its adaptability to different fabrication techniques ensures it remains a versatile option for engineers and architects.

With its growing popularity, understanding the intricacies of galvanized square steel becomes crucial for anyone involved in construction, engineering, or manufacturing. This article delves into the properties, applications, and benefits of this material, offering valuable insights for professionals and enthusiasts. By exploring its production process, environmental impact, and market trends, readers will gain a comprehensive understanding of why galvanized square steel continues to dominate the material landscape.

Read also:Mastering Insurance Ppc Management Strategies For Success

What Makes Galvanized Square Steel Ideal for Construction Projects?

Galvanized square steel offers unparalleled advantages that make it a preferred choice for construction projects. Its primary feature lies in its corrosion-resistant properties, achieved through a meticulous hot-dip galvanization process. During this process, the steel is submerged in molten zinc, forming a robust protective layer that shields it from environmental degradation. This coating not only enhances its durability but also extends its lifespan, making it suitable for long-term projects.

Beyond its corrosion resistance, galvanized square steel exhibits superior strength and stability. Its square shape provides enhanced structural support, making it ideal for load-bearing applications. Additionally, its uniform dimensions ensure precise fitting during construction, reducing the need for additional adjustments and minimizing material wastage. These attributes contribute to cost savings and improved project efficiency, further solidifying its position as a leading material in the construction industry.

Why Should You Choose Galvanized Square Steel for Your Next Project?

When selecting materials for construction or manufacturing, choosing the right option can significantly impact project outcomes. Galvanized square steel stands out due to its multifaceted benefits, addressing various needs of modern projects. Its adaptability to different fabrication techniques allows for customization, enabling it to meet specific design requirements. Moreover, its ease of maintenance ensures ongoing performance without the need for extensive upkeep, saving both time and resources.

Another compelling reason to choose galvanized square steel lies in its environmental sustainability. The galvanization process creates a durable coating that minimizes the need for replacements, reducing waste and promoting resource conservation. Additionally, its recyclability aligns with global efforts to reduce carbon footprints, making it an eco-friendly option for environmentally conscious projects. These attributes, combined with its cost-effectiveness, make it an attractive choice for both small-scale and large-scale applications.

How Does the Galvanization Process Enhance the Properties of Galvanized Square Steel?

The galvanization process plays a pivotal role in enhancing the properties of galvanized square steel. During this process, the steel undergoes a chemical reaction with molten zinc, forming a metallurgical bond that provides exceptional protection against corrosion. This protective layer not only prevents rust but also acts as a barrier against environmental contaminants, ensuring the material retains its strength and durability over time.

- The galvanization process involves cleaning the steel surface to remove impurities.

- It is then dipped into a bath of molten zinc at temperatures exceeding 840°F.

- The zinc reacts with the steel, creating a series of zinc-iron alloy layers.

- These layers provide a durable coating that enhances the material's resistance to abrasion and impact.

Applications of Galvanized Square Steel in Modern Industries

The versatility of galvanized square steel extends across various industries, finding applications in construction, automotive, agriculture, and more. In construction, it serves as a fundamental material for structural frameworks, fencing, and roofing systems. Its strength and durability make it suitable for supporting heavy loads, ensuring safety and stability in building projects. In the automotive sector, it is utilized in manufacturing vehicle components due to its ability to withstand harsh conditions and maintain performance.

Read also:True Beauty Actors Unveiling The Stars Behind The Hit Kdrama

Agricultural applications benefit from the corrosion-resistant properties of galvanized square steel, using it for constructing livestock enclosures, irrigation systems, and storage facilities. Its resistance to environmental factors ensures longevity and reliability in outdoor settings. Furthermore, its aesthetic appeal makes it a popular choice for decorative structures, enhancing visual appeal while maintaining functionality.

What Are the Environmental Benefits of Using Galvanized Square Steel?

As sustainability becomes a priority in material selection, galvanized square steel offers significant environmental advantages. Its production process incorporates recycled materials, reducing the demand for raw resources and minimizing environmental impact. Additionally, the galvanized coating extends the material's lifespan, decreasing the frequency of replacements and associated waste. These attributes contribute to its classification as an eco-friendly material, aligning with global sustainability goals.

Can Galvanized Square Steel Be Used in Residential Projects?

Absolutely, galvanized square steel finds extensive use in residential projects due to its versatility and durability. It serves as a primary material for constructing fences, gates, and railings, providing security and aesthetic appeal. Its resistance to corrosion ensures it remains intact in outdoor environments, requiring minimal maintenance. Moreover, its structural integrity makes it suitable for supporting balcony railings, pergolas, and other load-bearing components, enhancing the safety and functionality of residential spaces.

How Does Galvanized Square Steel Compare to Other Building Materials?

When compared to other building materials, galvanized square steel offers distinct advantages. Unlike untreated steel, it resists rust and corrosion, ensuring long-term performance. Compared to aluminum, it provides superior strength and load-bearing capabilities, making it more suitable for structural applications. Furthermore, its cost-effectiveness surpasses that of stainless steel, offering similar performance at a fraction of the price. These comparisons highlight its versatility and value, positioning it as a preferred choice for diverse projects.

Market Trends and Future Prospects of Galvanized Square Steel

The market for galvanized square steel continues to grow, driven by advancements in technology and increasing demand for sustainable materials. Innovations in production processes have enhanced its performance, expanding its applications across various sectors. As industries prioritize eco-friendly solutions, the demand for galvanized square steel is expected to rise, driven by its environmental benefits and cost-effectiveness. Future developments may focus on improving its recyclability and reducing production emissions, further solidifying its position as a leading material in the construction and manufacturing industries.

Table of Contents

- Understanding the Versatility of Galvanized Square Steel: A Comprehensive Guide

- What Makes Galvanized Square Steel Ideal for Construction Projects?

- Why Should You Choose Galvanized Square Steel for Your Next Project?

- How Does the Galvanization Process Enhance the Properties of Galvanized Square Steel?

- Applications of Galvanized Square Steel in Modern Industries

- What Are the Environmental Benefits of Using Galvanized Square Steel?

- Can Galvanized Square Steel Be Used in Residential Projects?

- How Does Galvanized Square Steel Compare to Other Building Materials?

- Market Trends and Future Prospects of Galvanized Square Steel

- Conclusion: Embracing the Potential of Galvanized Square Steel

Conclusion: Embracing the Potential of Galvanized Square Steel

In conclusion, galvanized square steel represents a remarkable material that combines strength, durability, and sustainability. Its widespread adoption across various industries underscores its versatility and value, making it an indispensable choice for modern projects. As technology continues to evolve, the potential applications of galvanized square steel will undoubtedly expand, offering innovative solutions for future challenges. By embracing its capabilities, professionals and enthusiasts can harness its full potential, contributing to the advancement of construction, manufacturing, and beyond.

Article Recommendations